Capabilities

CNC Milling

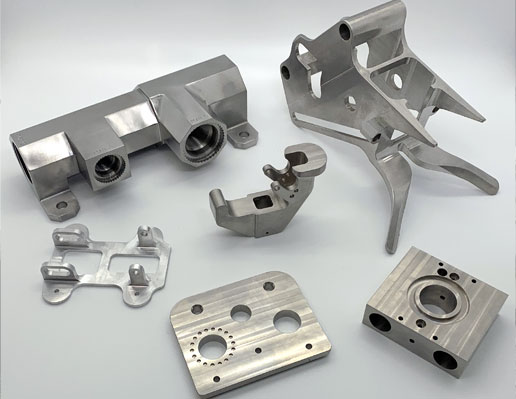

Our CNC Milling Department is comprised of six CNC Mills capable of 40” x 22” Milling. We are capable of machining 3, 4, and 5 Axis Milling. If it’s one part or ten thousand, we can design a program to fit each in individual need. Our extensive knowledge in designing and building custom fixturing to aid in the manufacturing high production and complex parts is what sets us apart from our competitors. Automation Managers, Inc. continuously invests in the latest technology in an effort to improve Quality, Cost, and Throughput. This translates into higher quality components at a fair and competitive price with improved turnaround times.

Mills

2012 Okuma GENOS M560-V

Travel X 41.34”, Y 22.05”, Z 18.11”

15,000 RPM Spindle

30 Tool Side Mount Changer

1000psi Thru Spindle Coolant

15” Nikken Rotary Table

2017 Doosan DNM 500II

Travel X 44”, Y 22.”, Z 20”

12,000 RPM Spindle

30 Tool Side Mount Changer

300psi Thru Spindle Coolant

Rienshaw Inspection Probe

2018 Doosan DNM 4500

Travel X 32”, Y 18.”, Z 20”

12,000 RPM Spindle

30 Tool Side Mount Changer

300psi Thru Spindle Coolant

Rienshaw Inspection Probe

ATS RT-260 Rotary Table

2005 HAAS VF-3

Travel X 40”, Y 20.”, Z 25”

7,500 RPM Spindle

20 Tool Side Mount Changer

5 Axis TR160 Rotary Table

HRT A6 Rotary Table

2006 HAAS VF-2

Travel X 30”, Y 16.”, Z 20”

7,500 RPM Spindle

20 Tool Side Mount Changer

4th Axis HRT A6 Rotary Table

4th Axis HA5C Indexer

2006 HAAS MINI MILL

Travel X 16”, Y 12.”, Z 10”

7,500 RPM Spindle

10 Tool Side Mount Tool Changer

4th Axis HA5C Indexer